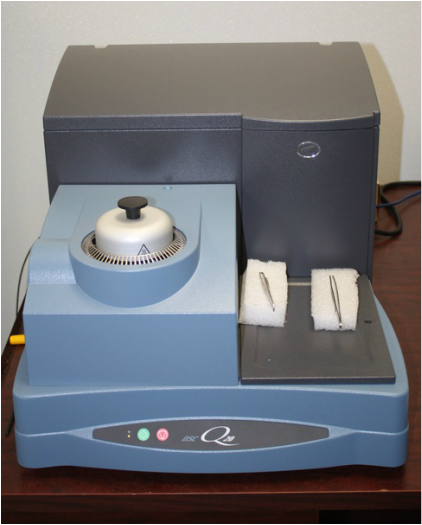

Quality Lab

We offer on-site testing to ensure the integrity and highest quality standards of our coating process.

Conducted Tests

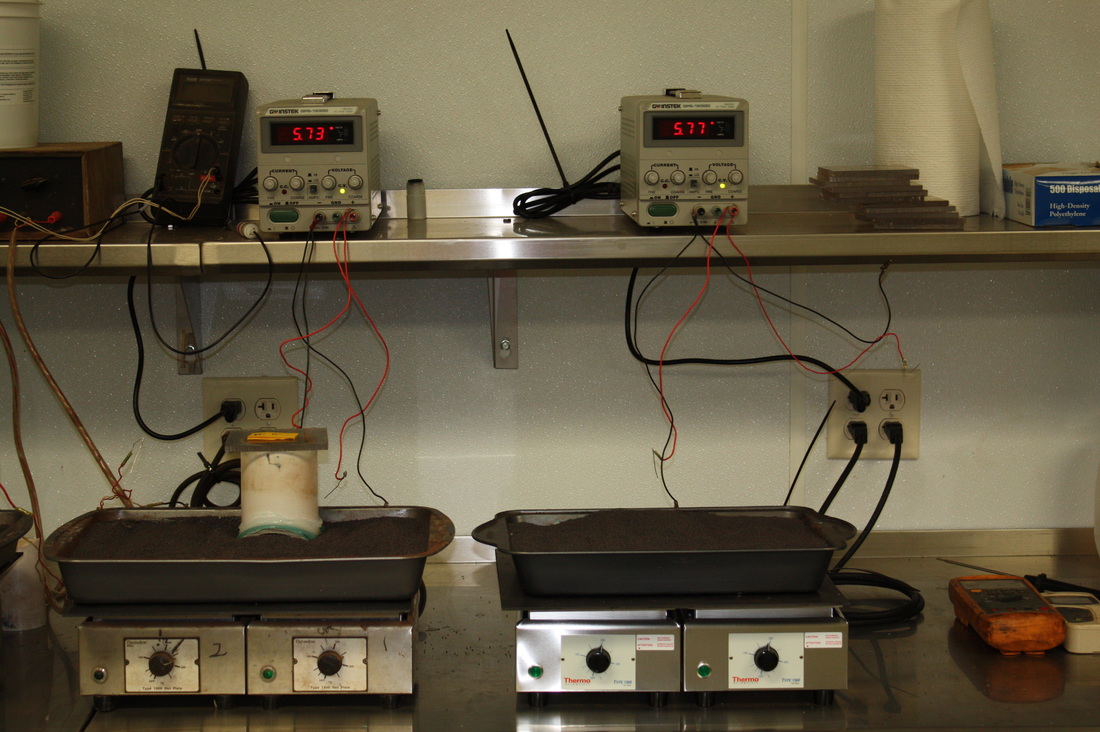

Cathodic Disbondment Test – Provides an assessment of the resistance of the coating to disbondment when subjected to cathodic disbondment.

Hot Water Soak – Provides an accelerated assessment of the coating’s adhesion to the substrate in a hot, wet environment.

Flexibility – Evaluates the flexibility of the coating to field bending.

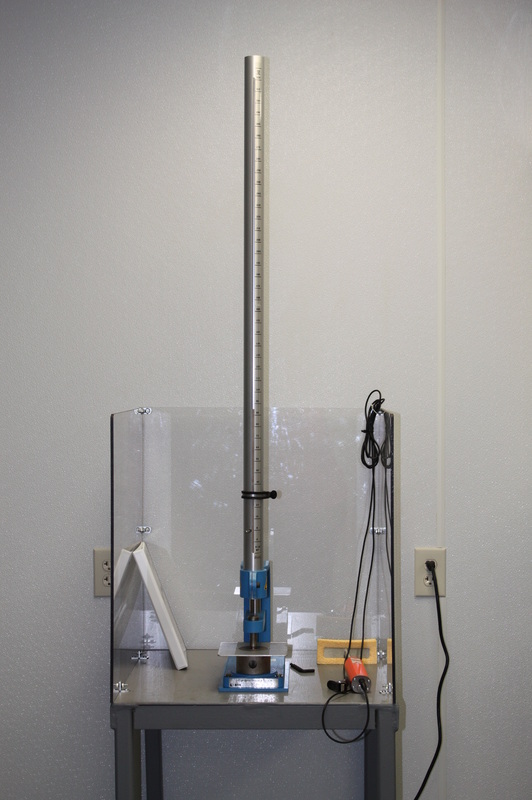

Impact Test – Assesses the coating’s resistance to damage by impact.

Porosity Test – Determines the degree of porosity or voids in the applied coating.

Contamination Verification – Determines the amount of contamination on the pipe surface prior to coating application.